How To Shrink Tint Back Window

Some windows are completely flat and will not crave to exist estrus shrunk. Normally the heat shrinking is needed when the contour of the drinking glass curves horizontally and vertically (like the rear windows of most modern cars).

1. Clean the outside of the window.

two. Make clean the window from the within:

ii.i. Spray the window with cleaning solution.

2.2. Utilise toothbrush to carefully clean the defroster plugs.

2.3. Spray with solution and scrub the whole window with white pad (don't utilize a lot pressure).

ii.4. Use the squeegee to remove the solution from the glass.

2.five. Spray the inside of the window one more than time (from meridian to lesser) to remove all the clay that may exist there.

2.half-dozen. Remove the solution with squeegee.

2.7. Wipe make clean using a lint gratis towel.

2.8. Check the rear window for scratches and fries (if you have they'll be visible later on installation).

3. Cut the pattern (non needed if you lot use our pre-cut automotive window tint pic patterns).

The pattern is measured and cutted on the outside of the rear window.

Now that you given the rear window a good inspection and cleaning, it'due south fourth dimension to cut a movie pattern to the shape you need. Make sure your measurements are exact so the picture show can exist hands installed. Please keep using the following steps:

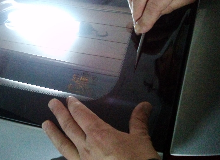

3.1. Place the picture show on the outside of the rear window, cut a rough design, be sure that the factory edge is on the top and lesser and the liner should be facing you.

3.2. Light an extra lamp on the inside of the automobile (the lite coming from the inside will assistance yous while cut the blueprint).

3.iii. Cut the flick using mild pressure 1-2cm after the dot matrix (in the black border zone). Always utilise new blades.

4. Shrink (wet shrink):

four.ane. Lift the film and spray with solution.

4.2. Form a "H" on the rear window with ane horizontal and two vertical motions the film should stuck to the glass.

iv.3. You'll go some "fingers", conform the movie and then the fingers run but from the centre to the lesser and to the top of the glass (just vertically). You tin can't heat shrink fingers out horizontally, they must be fabricated to run vertically (whatever fingers need to be in the same direction as the factory edge).

4.4. Split the larger fingers into smaller ones,if the fingers are large it'll hard to shrink them.

4.five. Turn on your heat gun (y'all tin use powerful hair dryer - 2000W), the heat will soften the film assuasive it to "shrink" back to its original form before it was stretchedще during the manufacturing process. The release of this built up tension allows the film to grade to the curve of the rear window

4.6. Starting time with a finger in the upper department. Estrus the pic with the estrus gun, holding it most five-6cm abroad from the bottom part of the finger, slowly apply the heat down the finger (don't keep the heat gun at one identify for long or yous'll harm the film). The heat will cause the finger to "milk shake" as it evaporates away. Smooth the motion picture out by using the hard carte. Echo with the other "fingers".

4.7. It is now time to brand the final cutting, when the film is already shrank and shaped to the window. Make a cut iii-four mm longer than the dot matrix (black border) around the unabridged rear window. E'er utilize a new blade.

v. Installation of the film design:

The film is fitted in the inside of the window

5.1. When you have completed the estrus shrinking prepare the inside of the window so the film can be hands installed.

5.2. Remove the liner (spray the agglutinative with solution while you remove the liner).

5.3. Spray the inside of the window (thoroughly) from top to bottom, that way you'll be able to remove even the smallest particle, because it could exist a problem if y'all left some kind of dirt (it volition form little bubbles and spots under the picture show).

v.4. At present that the inside of the window is clean and well sprayed every bit is the motion-picture show, you tin follow the last step.

5.v. Carefully take the film and put it, with the adhesive side you sprayed, onto the within of the drinking glass. Check for any light gaps.

five.half dozen. Spray the surface of the film with solution and then you tin run the difficult card/duster hands.

5.7. Start pushing the solution out with the hard card/squeegee from the center to the edges of the window using slight pressure until the film fits perfectly on the window.

5.eight. Wrap a paper towel around the squeegee/hard bill of fare and re-squeegee the entire window with slightly higher pressure. Repeat until all fingers and solution betwixt the glass and the film are gone.

The "wet shrink" method can be used for some side windows that accept horizontal and vertical curves.

Cheque the installation of the film:

• Later on the flick is installed is fourth dimension for one last inspection to be sure you didn't miss anything and the job is done correctly.

• Spray the outside of the window with solution and wipe clean using a newspaper towel.

• Allow the film to sit at to the lowest degree for 30 minutes before cleaning the inside of the window so you don't accidentally pull it off.

• During this fourth dimension you can install film on the other windows.

• Get the automobile out in direct sun light and check the window from outside.

• It'due south recommended to wait 5-6 days earlier cleaning the window.

• It is possible to be left with some moisture spots (bubbles) that will exist cleared after iii-4 days. This water will evaporate through the film.

Tip:When yous use pre-cut patterns, always remove the extra pic that surrounds the design first. The merely thing left on the bankroll liner should be the patterns that you are going to utilize.

Source: https://tintcom.com/en/Automotive_window_film_installation_manual_Rear_Window_wet_shrink_-p6790

Posted by: mcquaiddeak1989.blogspot.com

0 Response to "How To Shrink Tint Back Window"

Post a Comment